The Ones That Are Actually Asked

Last week I shared the list of questions asked by a group of Scouts. This week I’ll begin to answer them.

As I pointed out last week, due to the number of questions I’m going to divide them into different topics to keep the posts from getting too long. This week I’ll start by answering some basic construction questions. Keep in mind that asking and answering questions is communication and communication is a two-way process. This means that before I can answer questions fully and accurately, I need some questions answered.

As I pointed out last week, due to the number of questions I’m going to divide them into different topics to keep the posts from getting too long. This week I’ll start by answering some basic construction questions. Keep in mind that asking and answering questions is communication and communication is a two-way process. This means that before I can answer questions fully and accurately, I need some questions answered.

How much does building a new house cost?

This is the most common first question. It only makes sense; cost is a critical part of deciding whether to build. It’s also one of the most difficult to answer, especially when asked without any specifics.

This is the most common first question. It only makes sense; cost is a critical part of deciding whether to build. It’s also one of the most difficult to answer, especially when asked without any specifics.

Here are some of the questions that need answered to determine a price:

- Where will it be located? – location effects things like utilities, sewer, lot preparation, zoning, permitting, etc.

- How big? – more square feet costs more.

- How many levels? – stacked is typically less expensive per square foot.

- Type of foundation? – slab, crawl space or basement.

- How high are the ceilings? – higher is more expensive.

- What style of roof? – more complicated costs more.

- How many windows? – more windows cost more.

- Quality of materials and finishes? – there’s a wide variation in quality which translates into a wide variety of price, i.e. cabinets, countertops, flooring, light fixtures, plumbing fixtures, etc.

This is some of the things that need to be determined before getting an accurate price.

As a vague answer to a vague question, in the middle part of the US where we do construction, you can figure an average home to cost $110.00 to $150.00 per square foot of living space.

How long does it take to build a new house?

The answer to this question will be directly connected to the answers of the last question. Size, design, level of finish, etc. will all effect the length of time to build a new house. An average 2000 square foot home will take 6 – 9 months.

The answer to this question will be directly connected to the answers of the last question. Size, design, level of finish, etc. will all effect the length of time to build a new house. An average 2000 square foot home will take 6 – 9 months.

How much wood does a new house take?

Once again, the answer is going to depend on specifics of the house. Let’s just answer the question using the average 2000 square foot house that we have been using. Let’s assume that it’s going to have wood floor joists, sub-floor, wall studs, wall boxing, ceiling joists, rafters, roof sheathing, siding, windows, doors, cabinets, etc. All these things combined will be around 40 pounds per square foot. That means the wood used in a 2000 square foot house will weigh around 80,000 pounds, or 40 tons.

Once again, the answer is going to depend on specifics of the house. Let’s just answer the question using the average 2000 square foot house that we have been using. Let’s assume that it’s going to have wood floor joists, sub-floor, wall studs, wall boxing, ceiling joists, rafters, roof sheathing, siding, windows, doors, cabinets, etc. All these things combined will be around 40 pounds per square foot. That means the wood used in a 2000 square foot house will weigh around 80,000 pounds, or 40 tons.

How much steel goes into a house?

There are some cases where houses are framed using steel, but typically that’s not very common. There are some steel things commonly used, like nails, screws, joist hangers, reinforcing steel in concrete, etc. Sometimes steel beams and posts are used for supporting heavier loads and wider spans. In a typical wood framed house, it takes around 10 pounds of steel reinforcing, fasteners and misc. per square foot to build. This means that our 2000 square foot wood framed home would have around 20,000 pounds or 10 tons.

There are some cases where houses are framed using steel, but typically that’s not very common. There are some steel things commonly used, like nails, screws, joist hangers, reinforcing steel in concrete, etc. Sometimes steel beams and posts are used for supporting heavier loads and wider spans. In a typical wood framed house, it takes around 10 pounds of steel reinforcing, fasteners and misc. per square foot to build. This means that our 2000 square foot wood framed home would have around 20,000 pounds or 10 tons.

Next week we’ll answer questions about the construction process. If you have any construction questions you would like answered, asked them in the comments below.

Quality, honesty and integrity cover this part of the list. These are character issues. They are about choosing to give as much importance to someone else’s needs as I do my own.

Quality, honesty and integrity cover this part of the list. These are character issues. They are about choosing to give as much importance to someone else’s needs as I do my own. The entire issue of construction projects falling apart is unnecessary and unacceptable.

The entire issue of construction projects falling apart is unnecessary and unacceptable.

Cost overruns – You’ve saved and/or borrowed the money you predict you’ll need to do the upcoming construction project. You get an estimate of what it’s going to cost. Sure, it’s more than you expected, but that’s alright it will be worth it in the end, right. Then you get the final bill and it’s a lot more than expected. Now what? Where are you going to find the additional money?

Cost overruns – You’ve saved and/or borrowed the money you predict you’ll need to do the upcoming construction project. You get an estimate of what it’s going to cost. Sure, it’s more than you expected, but that’s alright it will be worth it in the end, right. Then you get the final bill and it’s a lot more than expected. Now what? Where are you going to find the additional money?

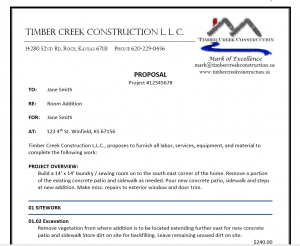

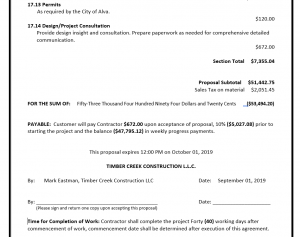

This problem can, and should, be addressed before any actual construction begins. The underlying issue with any disagreement is, different people seeing things differently. A good contractor’s job is to sort through these differences and develop a clear picture of the project scope, design, schedule and price.

This problem can, and should, be addressed before any actual construction begins. The underlying issue with any disagreement is, different people seeing things differently. A good contractor’s job is to sort through these differences and develop a clear picture of the project scope, design, schedule and price. The first four…half of the list, are communication related. Good communication takes time and effort. Time and effort translate into additional cost. Additional cost means your project’s price is higher. Price is important and often leads to choosing a lower bid. Full circle back to the importance of communication. If you are aware of the differences and are presented a clear plan, you can make the best decision for you and your project.

The first four…half of the list, are communication related. Good communication takes time and effort. Time and effort translate into additional cost. Additional cost means your project’s price is higher. Price is important and often leads to choosing a lower bid. Full circle back to the importance of communication. If you are aware of the differences and are presented a clear plan, you can make the best decision for you and your project.

Day 4 Thursday – We laid rest of the east-west rows of ties, spread more fill and moved the remaining rolls of turf to the areas where the pad was prepped. I began digging the hole in the sand and gravel for the paw shaped pool to set in. To minimize future settling and give us the best base we began compacting with a vibrating compactor. This meant we needed to temporarily roll the first turf back out of the way of the compactor. It wasn’t fastened yet, so this wasn’t much of an issue.

Day 4 Thursday – We laid rest of the east-west rows of ties, spread more fill and moved the remaining rolls of turf to the areas where the pad was prepped. I began digging the hole in the sand and gravel for the paw shaped pool to set in. To minimize future settling and give us the best base we began compacting with a vibrating compactor. This meant we needed to temporarily roll the first turf back out of the way of the compactor. It wasn’t fastened yet, so this wasn’t much of an issue.

Day 9 Tuesday – Things are coming together. We reset the chain link fence in the new location, reattached the remaining fence to the building, hung the panels back in the end of the building. Using up the last of the ties, most of the sand, last of the gravel, and we built a raised pad for the new private cottage to sit on. Due to the elevation around the cottage pad we installed some drain tile to one of the downspouts on the original building and buried it in gravel to prevent water from becoming a pond. Next we moved the cottage onto the new pad.

Day 9 Tuesday – Things are coming together. We reset the chain link fence in the new location, reattached the remaining fence to the building, hung the panels back in the end of the building. Using up the last of the ties, most of the sand, last of the gravel, and we built a raised pad for the new private cottage to sit on. Due to the elevation around the cottage pad we installed some drain tile to one of the downspouts on the original building and buried it in gravel to prevent water from becoming a pond. Next we moved the cottage onto the new pad.

Ann owns and operates

Ann owns and operates

In one corner of the run there will be a small paw shaped pool with a fountain. This will require figuring out the best way to get the water from the pool to the pump and to the fountain. In the future there will be an old fire hydrant serving as the fountain, so this needs to be allowed for now.

In one corner of the run there will be a small paw shaped pool with a fountain. This will require figuring out the best way to get the water from the pool to the pump and to the fountain. In the future there will be an old fire hydrant serving as the fountain, so this needs to be allowed for now. The most challenging part is building the tunnel/hill. We needed to determine what we were going to use for this. We considered pipes, barrels, tanks with the ends cut out and a few other things. Then we found some concrete culverts and the price was right, so this is what we decided on.

The most challenging part is building the tunnel/hill. We needed to determine what we were going to use for this. We considered pipes, barrels, tanks with the ends cut out and a few other things. Then we found some concrete culverts and the price was right, so this is what we decided on.

Clean garbage disposals – Put a little vinegar in an ice cube tray, add some water and freeze, then run some cubes through the disposal. Follow up with a little baking soda and warm water. The ice cubes will sharpen the blades, the vinegar and baking soda will break down food and grease build up and will leave it smelling fresh and clean.

Clean garbage disposals – Put a little vinegar in an ice cube tray, add some water and freeze, then run some cubes through the disposal. Follow up with a little baking soda and warm water. The ice cubes will sharpen the blades, the vinegar and baking soda will break down food and grease build up and will leave it smelling fresh and clean. Clean faucet aerators and shower heads – Dirty aerators on the end of your faucets and in shower heads can mean limescale and sediment are blocking the flow and water pressure. Unscrew the aerators and shower heads, remove the aerator and/or screen, soak them in a 50/50 vinegar/water mixture for 30 minutes or until clean, rinse and reinstall. Be careful to pay attention to the order and direction the parts come apart so that you can put them back together correctly.

Clean faucet aerators and shower heads – Dirty aerators on the end of your faucets and in shower heads can mean limescale and sediment are blocking the flow and water pressure. Unscrew the aerators and shower heads, remove the aerator and/or screen, soak them in a 50/50 vinegar/water mixture for 30 minutes or until clean, rinse and reinstall. Be careful to pay attention to the order and direction the parts come apart so that you can put them back together correctly. Lubricate and test overhead garage door – Garage doors have moving parts that should be lubricated. With the door closed clean dirt and debris from the track. Use a lithium-based aerosol and spray rollers, bearings and other moving parts of the door and opener (chain or threaded rod). Your garage door should have stop and auto reverse motion detection to sense if an object is in its path. Get a 2×4 piece of wood and place it underneath the open door, then close the door using the opener button. The door should stop closing once it detects the wood and go back up. Also test the photo-electric sensors by moving something in front of them while the door is coming down, it should reverse direction and go back up.

Lubricate and test overhead garage door – Garage doors have moving parts that should be lubricated. With the door closed clean dirt and debris from the track. Use a lithium-based aerosol and spray rollers, bearings and other moving parts of the door and opener (chain or threaded rod). Your garage door should have stop and auto reverse motion detection to sense if an object is in its path. Get a 2×4 piece of wood and place it underneath the open door, then close the door using the opener button. The door should stop closing once it detects the wood and go back up. Also test the photo-electric sensors by moving something in front of them while the door is coming down, it should reverse direction and go back up.

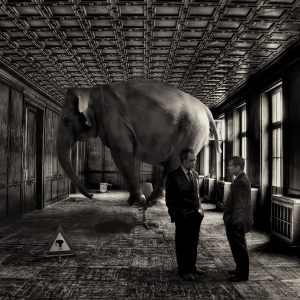

The complete list can certainly seem overwhelming. This is a big part of why routine maintenance gets overlooked. If you break it down into the individual tasks, spread them out and schedule them, it’s doable, like eating an elephant one bite at a time.

The complete list can certainly seem overwhelming. This is a big part of why routine maintenance gets overlooked. If you break it down into the individual tasks, spread them out and schedule them, it’s doable, like eating an elephant one bite at a time.