It’s Important to Know This Because Your Money Can Move with It

It’s that time of the year again; temperatures on the thermometer are creeping near the 100-degree mark. This raises the issue of keeping the heat outside and the cool air inside.

This issue is even more relevant if you live in a home that is 40 years old or older.

A home built before the mid-seventies is more likely affected by outside temperatures. Not enough insulation, single-pane windows, and air infiltration are all issues that may need attention.

Understanding how heat moves in and out of your home can help you determine what projects to consider undertaking to minimize the heat. It can also help determine which projects are most important.

There is a difference between heat and hot air.

A basic misunderstanding is that heat flows upward. This is not the case. Although, hot air rises because it is less dense than cool air.

Heat is unaffected by gravity and flows in all directions.

For example, if you apply a heat source to the center of a metal block, the bottom will get just as hot as the top and sides. Heat spreads in all directions and at the same rate.

Hot air is different. When the air in an attic or fireplace gets hot, the air begins to rise. This creates a draft or natural up flow. This is why vented ridges on roofs work so well.

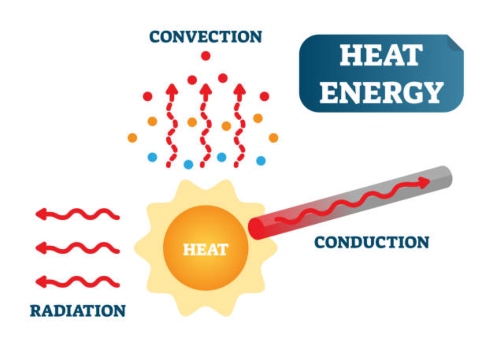

Heat moves through your home in three different ways. Each needs to be considered and will require different methods or products to control this heat transfer:

- First, conduction is like the metal block example above or the handle of a cast iron skillet on your stove. This is how heat moves through the walls, ceilings, and floors in your home. The temperature difference on either side of a wall determines how fast and which direction the heat will flow through it. The higher the R-value of insulation in that wall, the slower the heat transfer.

- Second, convection transfer is like conduction, but occurs in fluids and gases. When a cold wind is blowing outside, this increases the loss of heat through the wall more than if the air was still. This is the “wind chill” factor. Convection ovens use this form of heat transfer to cook by moving hot air. This is why they cook faster than conventional ovens.

- The last type of heat transfer is radiation, which is probably the most difficult of the three to understand. Radiation does not need a transfer material to move heat. This is how the sun warms the earth over millions of miles of empty space or how the top of a steak gets seared in the broiler. Radiant heat transfer is generally more of an issue in the summer but shouldn’t be ignored during the winter. Radiant heat is not blocked by standard insulation, but rather by reflectivity. An example of this would be the way dark colors of roofing, siding, etc. absorb heat and light colors reflect it.

All three of these are to blame for heat entering your home in the summer and leaving it in the winter.

Adequate wall and ceiling insulation, high-quality windows and doors would be a good place to begin. These can be expensive but will give you the biggest return on your investment.

There are several small ways to make improvements, including new weather stripping, filling voids in foundations with spray foam, sealing around electrical and plumbing openings, etc.

Also wind breaks (i.e. evergreen trees or privacy fences) can help.

NOW would be a good time to give some consideration to these issues before it gets even hotter.

Investing in these kinds of home improvements can help keep you cooler in the summer and warmer in the winter. They also provide an economic payback with lower utility bills.

Do what you can to keep the money in your home and minimize it being transferred with the heat.