How Can You Change the Odds in Your Favor?

According to the US Department of Commerce, 96% of construction companies fail within the first 10 years. This is a higher failure rate than any other kind of business.

If you’re in construction…this is a problem.

Having been in construction for more than 40 years, I understand how hard it can be to build a successful business. It takes a lot more than just knowing construction to be successful. Knowing business is as important as knowing construction.

Over those 40 years, I became aware of the problems and began to understand them. I gathered information and learned how to implement it into my business.

That’s why I beat the odds.

I’ve learned a lot over those forty-plus years and here are 7 reasons that construction companies fail:

- Insufficient Cash Flow – Without a positive cash flow, it is hard for construction companies to keep their doors open. A lack of cash flow makes it hard to pay for materials, make payroll, maintain tools, etc.

When cash flow is negative, companies often make hasty decisions or take on jobs that aren’t a good fit for their company. This can result in further profit loss and more cash flow problems.

- Unprofitable Projects – A lot of construction companies fail simply because their projects are unprofitable. Guessing at what a project is going to cost to do is not a very good plan. This is why having a proposal system that is consistent and accurate is essential to staying in business.

At Timber Creek Construction using our Proposal system, we consistently come in 25% under budget. This is in before overhead and profit.

- Doing Estimates Rather than Proposals – It’s essential to establish clear communication with construction customers. Creating a detailed proposal, rather than just estimating, gives both the construction company and the customer a clear understanding of what will be provided and what they can expect. Following up with a contract is another step to achieving this goal.

There are as many bad customers out there as there are bad contractors. Some of those customers simply want to get the work done for free. They will argue about things that, they claim, were promised. A signed proposal and contract will help to prevent this from happening.

- No Production Payment Plan – Having an accurate and understandable payment schedule with construction customers will set your construction company on the road to success. Not having a payment schedule requires your company to finance the project and consumes your cash flow. You are not a bank.

In my experience, you need to get some money prior to starting a project. This amount will depend on the size and type of project. Then invoice the customer with weekly progress payments that coincide with the percentage of completed work as outlined in the proposal. Customers appreciate a well-documented payment schedule that communicates clearly.

- Not Using Change Orders – Unforeseen issues and changes creep into most construction projects of any size. Changes orders are needed when changes are made to the project’s scope of work. When a job change occurs, the construction company should submit a change order to the customer for approval. Waiting until the end of the job to bill for additional costs will be problematic. It will often result in customers being upset, giving bad reviews, and resisting paying.

Customers get excited about the work that is being done until the final bill comes. Then they find themselves over extended and unable to pay.

- Poor Customer Service – Most construction companies don’t listen to their customers very well. These companies just focus on completing the work according to the contract. If they get paid, they assume all is good. But remember, construction companies are in the business of serving customers, this includes communicating clearly and consistently.

Most customers will only do a handful of sizable construction projects in their lifetime. Construction companies should remember this and help them build their dream.

- Lack of Organization and Processes – Building a sustainable construction business is impossible when the bulk of the business is operating without being organized. To stay in business, you need processes and systems that can be efficiently managed by the people you hire to help you.

For companies that use sticky notes and boxes full of folders, you have a problem.

Job leads and customer management, project details, task management, communications, schedules, progress tracking, equipment management, the list goes on and on. Each of these elements is extremely time-consuming, error prone, and can negatively affect profitability and cash flow.

You can avoid making the same mistakes most construction companies make by being aware of and understanding these problems. Then implementing and learning processes and systems to ensure that your company succeeds.

This will help you to be in the top 4% of businesses in the construction industry.

Successful construction companies use business tools to build, increase profits, and manage their businesses. Now that you have a clear understanding why construction companies fail, it’s time to make some course corrections.

To help you with this we have a Business Building Toolbox with tools that can help you change the odds in your favor. We also offer training and implementation of these tools into your business if that would be helpful. If you have questions, schedule a free 30-minute construction company consultation.

Ann owns and operates

Ann owns and operates

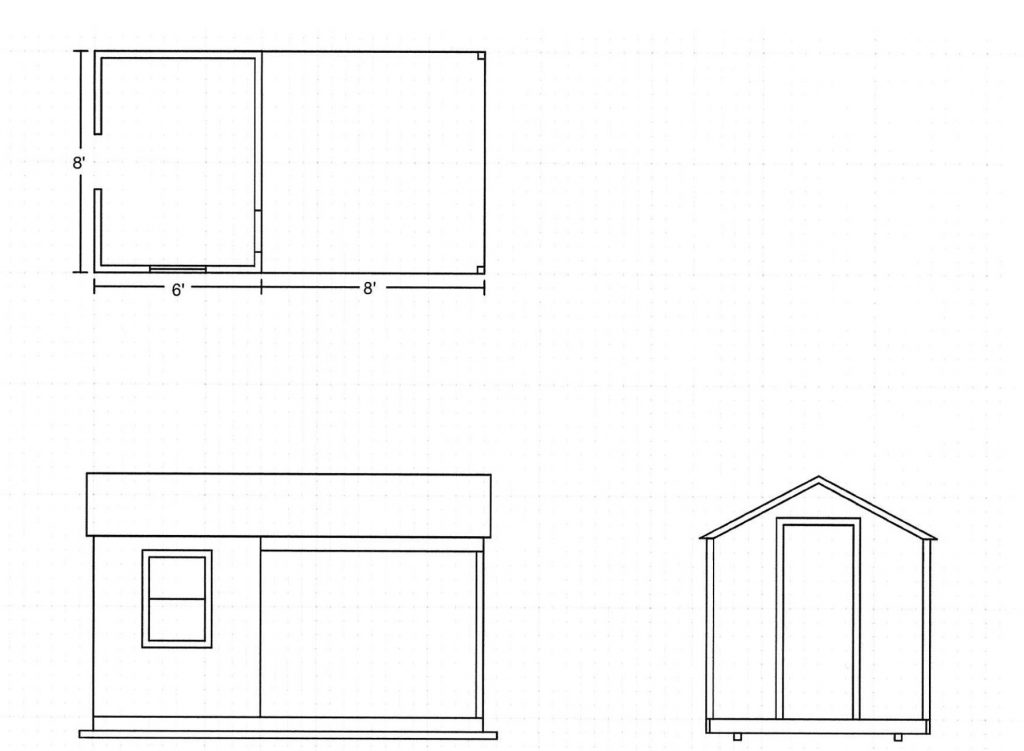

In one corner of the run there will be a small paw shaped pool with a fountain. This will require figuring out the best way to get the water from the pool to the pump and to the fountain. In the future there will be an old fire hydrant serving as the fountain, so this needs to be allowed for now.

In one corner of the run there will be a small paw shaped pool with a fountain. This will require figuring out the best way to get the water from the pool to the pump and to the fountain. In the future there will be an old fire hydrant serving as the fountain, so this needs to be allowed for now. The most challenging part is building the tunnel/hill. We needed to determine what we were going to use for this. We considered pipes, barrels, tanks with the ends cut out and a few other things. Then we found some concrete culverts and the price was right, so this is what we decided on.

The most challenging part is building the tunnel/hill. We needed to determine what we were going to use for this. We considered pipes, barrels, tanks with the ends cut out and a few other things. Then we found some concrete culverts and the price was right, so this is what we decided on.